The Importance Wall Expansion Joint Covers

HOW THEY PROTECT YOUR BUILDING AND ENSURE STRUCTURAL INTEGRITY

The significance of an expansion joint is frequently emphasized, yet the equally vital component that plays a crucial role in the wall expansion joint cover is often overlooked in discussions. They play a crucial role in safeguarding buildings from the detrimental impact of temperature variations, seismic activity, and various environmental elements.

Expansion joint covers serve a crucial role in protecting buildings against potential issues like cracks, leaks, and structural instability resulting from the inherent movement of building materials.

Not only do they create a protective shield against moisture penetration, but they also play a vital role in enhancing fire resistance and sound insulation. In this article, we will talk about why wall expansion joint covers are important. We’ll look at their advantages and explain why it’s crucial to include them in building plans.

Whether you’re an architect, contractor, or own a building, knowing the importance of expansion joint covers is key to ensuring a building stays safe and steady for a long time.

WHAT IS WALL EXPANSION JOINT COVERS?

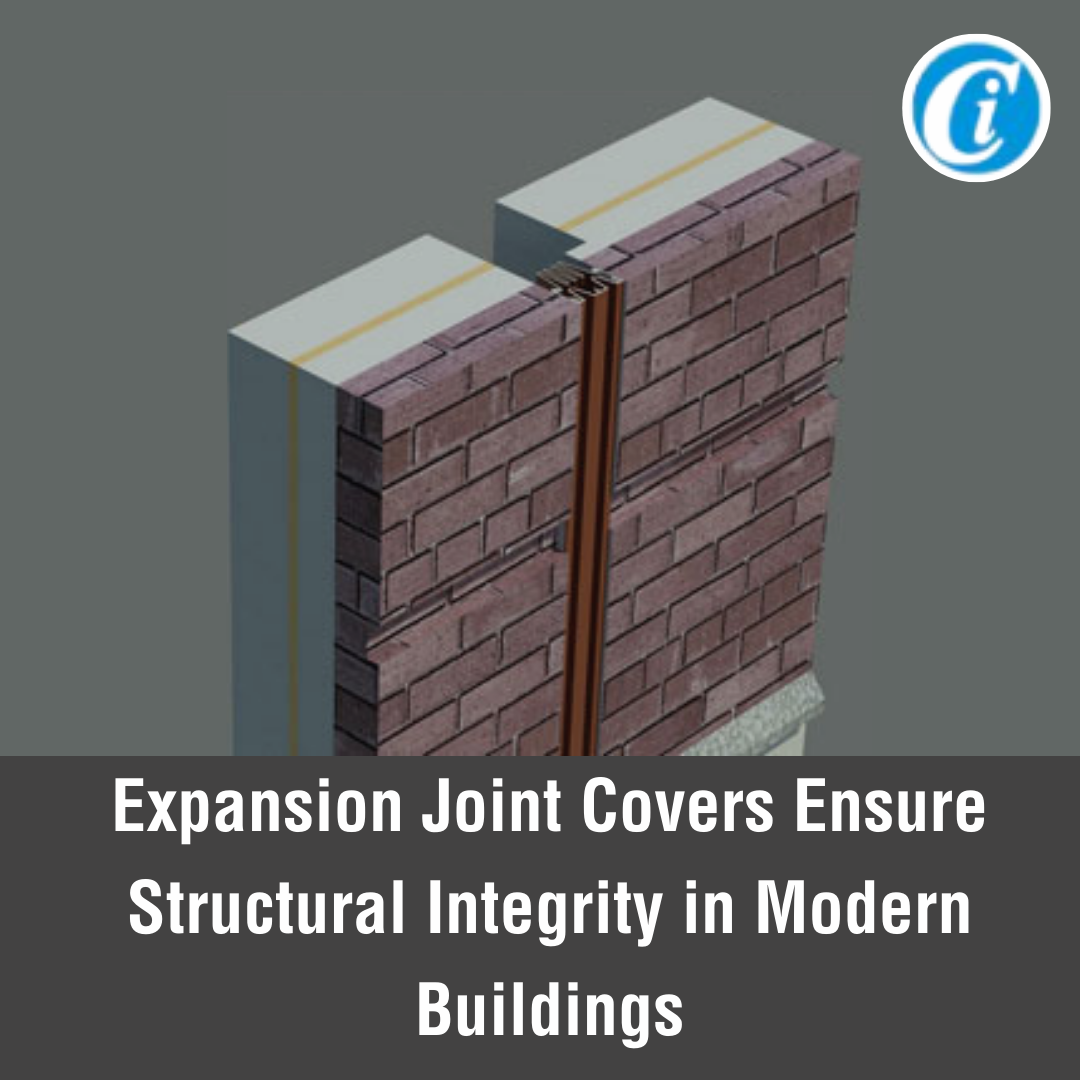

Wall expansion joint covers, or expansion joint cover plates, are crucial protective elements strategically placed in the gaps between various building components like walls, floors, or ceilings.

These components, especially expansion joint covers for concrete, play a pivotal role in accommodating the natural expansion and contraction of building materials. This is essential in handling temperature changes, seismic activity, wind loads, and other environmental factors.

The primary objective of these wall expansion joints cover is to establish a flexible barrier, allowing the movement of building materials while upholding structural integrity.

These covers, available in various shapes, sizes, and designs, cater to diverse building requirements and aesthetic preferences. They are typically constructed from robust materials like rubber, metal, or composite materials, ensuring durability.

These expansion joint systems find widespread application in different building types, spanning commercial buildings, hospitals, airports, stadiums, and residential structures. They are indispensable in both interior and exterior walls, particularly in critical junctions like corners, intersections, and floor-to-wall transitions.

In shopping malls and hospitals, specialized expansion joints for shopping malls and hospitals play a pivotal role. In concrete structures, expansion joint solutions are imperative, ensuring long-term stability. Whether it is expansion joints in concrete or those designed for floors and floor coverings, their incorporation is fundamental for ensuring the longevity and safety of the building.

THE ROLE OF WALL EXPANSION JOINT COVERS IN PROTECTING BUILDINGS

Wall expansion joint covers are crucial for safeguarding buildings from the impacts of temperature shifts, seismic activity, and environmental changes. These expansion joint covers for walls serve as protective plates, effectively absorbing and accommodating movements in building materials.

This prevents potential issues like cracks, leaks, and structural failures that could jeopardize safety and durability. Whether it is expansion joint covers for concrete or tailored systems for specific settings like hospitals, integrating these components ensures robust protection for the structure. Additionally, floor expansion joint covers are integral elements of such systems, reinforcing the overall structural integrity.

HOW WALL EXPANSION JOINT COVERS ENSURE STRUCTURAL INTEGRITY

Thermal expansion and contraction occur as building materials expand or contract with changing temperatures, placing stress on the structure. While imperceptible to the eye, this gradual process is prevalent in houses and buildings. It stands as a key factor in building damage, potentially causing cracks, fractures, and other forms of harm.

Wall expansion joint covers act as a pliable barrier, accommodating the movement of building materials and adeptly absorbing stress. They play a crucial role in preserving a building’s structural integrity, averting issues like cracks, leaks, and damage caused by natural material movement.

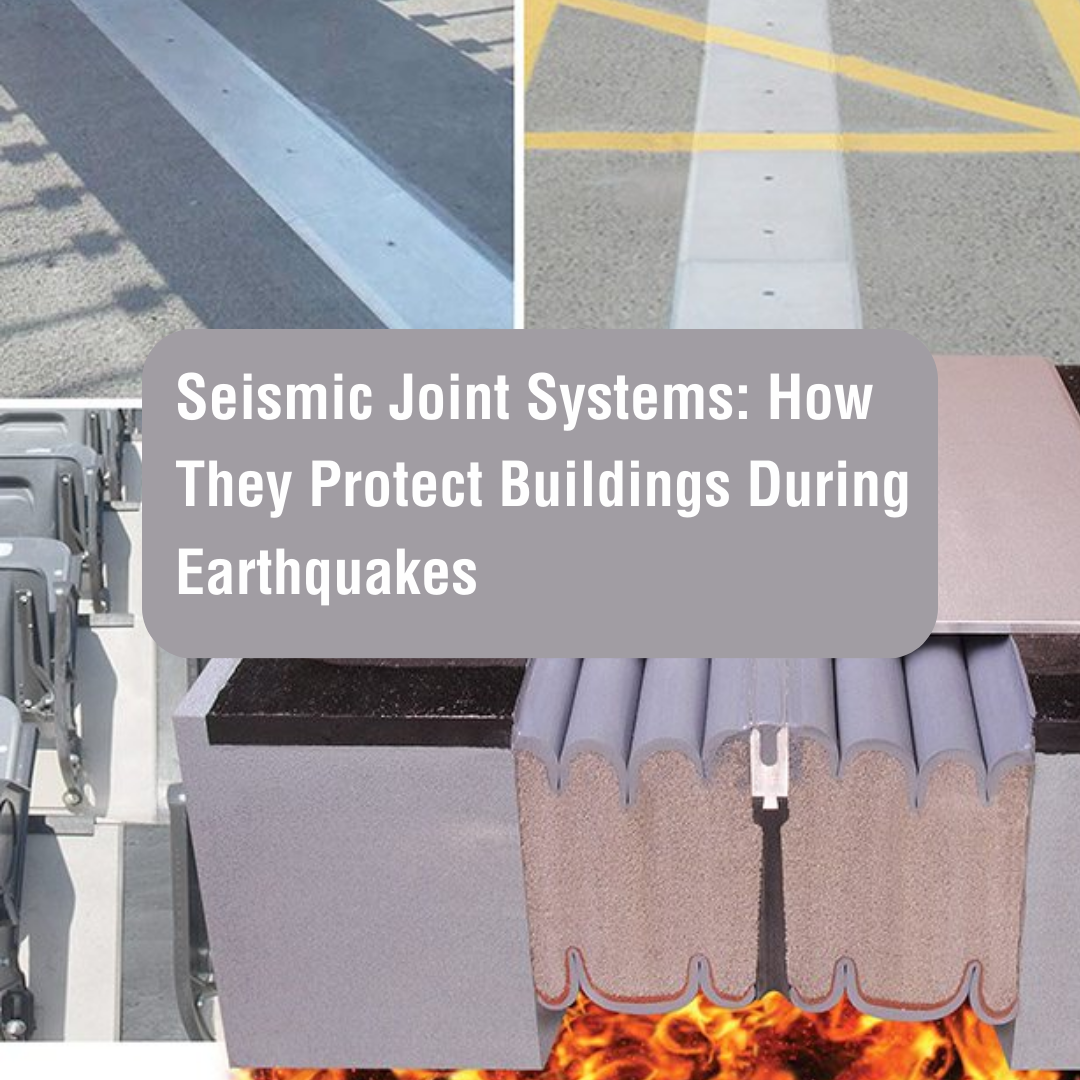

Apart from thermal shifts, wall expansion joint covers also account for seismic activity and wind loads. They offer flexibility to absorb the considerable forces exerted during earthquakes or strong winds, averting potential structural damage or collapse and ensuring the building’s stability and safety.

THE DIFFERENT TYPES OF WALL EXPANSION JOINT COVERS

There is a range of wall expansion joint covers, tailored to diverse building needs and aesthetic preferences. The selection depends on factors like building location, purpose, and design. Below are some of the prevalent types of these covers.

- COMPRESSION SEALS: Compression seals are pliable covers crafted from rubber or composite materials. Their design enables them to compress and expand in tandem with the building materials’ movement. Compression seals are commonly used in areas where large movements are expected, such as expansion joints in concrete walls or floors.

- SURFACE-MOUNTED COVERS: Surface-mounted covers are installed on top of the building components and are visible on the surface. They are available in various designs, such as metal plates, rubber strips, or composite materials. Surface-mounted covers are often used in areas where aesthetics is essential, such as in architectural features or high-traffic areas.

- FLUSH-MOUNTED COVERS: Flush-mounted covers are installed flush with the surface of the building components, creating a seamless appearance. Constructed from metal or composite materials, these covers ensure seamless transitions between various building components. Flush-mounted variants find common application in environments where both aesthetics and cleanliness hold paramount importance, notably in settings like healthcare facilities or cleanrooms.

- WATERPROOFING MEMBRANES: Waterproofing membranes play a vital role in safeguarding structures from water intrusion, especially in areas with expansion joints in concrete or flooring. These specialized membranes, typically composed of rubber or composite materials, are strategically installed beneath the building components’ surface.

They are particularly crucial in places like balconies, terraces, or swimming pool decks, where maintaining a waterproof barrier is essential. Utilizing advanced Expansion Joint Solutions, including reliable expansion joint systems, ensures that areas prone to seismic activity, use seismic joints in buildings or seismic separation joints, to remain well-protected.

FACTORS TO CONSIDER WHEN CHOOSING WALL EXPANSION JOINT COVERS

When planning about wall expansion joint covers, it’s important to consider various factors. These considerations are crucial in ensuring the covers deliver the best performance and have a long-lasting effect. Here are the key points to keep in mind:

- MOVEMENT CAPABILITY: It is essential to select expansion joint covers that can accommodate the expected movement of building materials. The covers should have the necessary flexibility and range of motion to absorb the stress caused by thermal expansion, seismic activity, and other environmental factors.

- DURABILITY: The materials used for wall expansion joint covers should possess durability, capable of withstanding environmental challenges. They must exhibit resistance to UV radiation, temperature fluctuations, moisture, chemicals, and other elements that could potentially lead to wear and early deterioration.

- AESTHETICS: The visual appeal of expansion joint covers can be significant, depending on the building’s purpose and location. These covers must come in a range of colours, shapes, and designs to harmonize with the overall building aesthetic.

- Maintenance: Consider how easy it is to clean and maintain the expansion joint covers. Certain covers may necessitate regular checks, cleaning, or even replacement to uphold their peak performance and durability.

- INSTALLATION: It’s crucial to think about how wall expansion joint covers are installed to make sure they fit and work correctly. Following the manufacturer’s instructions and specifications during installation is essential. This helps prevent any mistakes that could affect how well the covers work.

THE INSTALLATION PROCESS OF WALL EXPANSION JOINT COVERS

While the installation process of wall expansion joint covers can differ based on the cover type and specific building needs, there are some common steps to follow. Here is an overview of the general installation process:

- PREPARATION: Before the installation of expansion joint covers, it is essential to conduct a thorough cleaning and preparation of the surfaces where the covers will be placed. This involves the removal of any debris, dust, or loose materials to guarantee a secure adhesion and proper fit.

- MEASUREMENT AND CUTTING: Measure the length of the expansion joint and cut the cover to the appropriate size. It is important to follow the manufacturer’s guidelines and specifications during cutting to ensure precise fit and functionality.

- ADHESIVE APPLICATION: Spread the suggested adhesive or sealant evenly on both the back of the expansion joint cover and the intended installation surface. This ensures a robust and even bond between the cover and the surface.

- INSTALLATION: Gently press the expansion joint cover onto the surface, aligning it with the joint or gap. Apply steady pressure to ensure it adheres properly, removing any air bubbles or gaps. Always follow the manufacturer’s instructions for any extra steps or precautions that might be necessary.

- FINISHING: Once the expansion joint covers are installed, any excess adhesive or sealant should be carefully removed. The installation area should be cleaned and inspected to ensure proper fit and functionality.

COMMON PROBLEMS WITH WALL EXPANSION JOINT COVERS AND HOW TO ADDRESS THEM

While wall expansion joint covers are designed to provide reliable protection and ensure the structural integrity of a building, they can encounter some common problems over time:

- CRACKING OR SPLITTING: In certain situations, expansion joint covers can develop cracks or splits from prolonged exposure to UV radiation, extreme temperatures, or other environmental elements. To rectify this, it’s advisable to replace the damaged covers with new ones crafted from sturdier materials or better tailored to the specific environment.

- DISCOLORATION OR FADING: Over time, expansion joint covers in flooring may show discolouration from UV radiation. To address this issue, the covers can be cleaned or replaced with new ones that are resistant to discolouration or fading. This ensures a fresh look for your floor expansion joint.

- LOOSE OR DETACHED COVERS: Occasionally, expansion joint covers might loosen or detach from the surface due to issues like insufficient adhesive, improper installation, or excessive movement. To resolve this, it’s essential to reinstall or replace the covers, ensuring they adhere properly and fit securely.

- WATER INFILTRATION: If water infiltration occurs despite the presence of expansion joint covers, it may indicate a problem with the cover or the installation. To address this issue, the source of the water infiltration should be identified and corrected. This may involve replacing the cover, improving the sealant application, or addressing any underlying issues with the building envelope.

THE IMPORTANCE OF REGULAR MAINTENANCE FOR WALL EXPANSION JOINT COVERS

Maintaining wall expansion joint covers is crucial for their longevity and performance. It helps catch and fix issues before they can harm the building’s protection and structure. Here are vital maintenance practices for these covers:

- INSPECTION: Regularly inspect the expansion joint covers for any signs of damage, deterioration, or displacement. Look for cracks, splits, discolouration, or any other issues that may indicate a problem. Inspections should be carried out at least once a year or as recommended by the manufacturer.

- CLEANING: Clean the expansion joint covers regularly to remove any dirt, debris, or other contaminants that can compromise their performance. Use a mild detergent or cleaning solution and a soft brush or cloth to clean the covers gently. Avoid using harsh chemicals or abrasive materials that can damage the covers.

- SEALANT MAINTENANCE: Check the condition of the sealant or adhesive used to secure the expansion joint covers. Over time, the sealant may deteriorate or become loose, compromising the performance of the covers. If necessary, reapply or replace the sealant to ensure proper adhesion and functionality.

- REPAIR OR REPLACEMENT: If any issues or damage are identified during inspections, address them promptly. Repair or replace damaged covers, reapply sealant or take any necessary steps to ensure the optimal performance of the expansion joint covers.

THE SIGNIFICANCE OF INVESTING IN HIGH-QUALITY WALL EXPANSION JOINT COVERS FOR LONG-TERM BUILDING PROTECTION AND STRUCTURAL INTEGRITY

Investing in high-quality wall expansion joint covers is a wise decision for architects, contractors, and building owners. These durable yet inconspicuous components are an integral part of any building design, contributing to the long-term stability, safety, and protection of the structure. By incorporating wall expansion joint covers into building designs, professionals can ensure the structural integrity and longevity of the buildings they create.